Description

The Hydrothermal Liquefaction (HTL) capability provides expertise and bench-scale to engineering scale test systems to convert wet waste biomass feedstocks into pumpable slurries, processing them into HTL biocrude, and upgrading the biocrudes into jet, diesel, and marine fuel blend-stocks. This capability is focused on derisking and enabling process scale up and commercialization and directly linked to geographic feedstock resource analysis, technoeconomic and sustainability analysis.

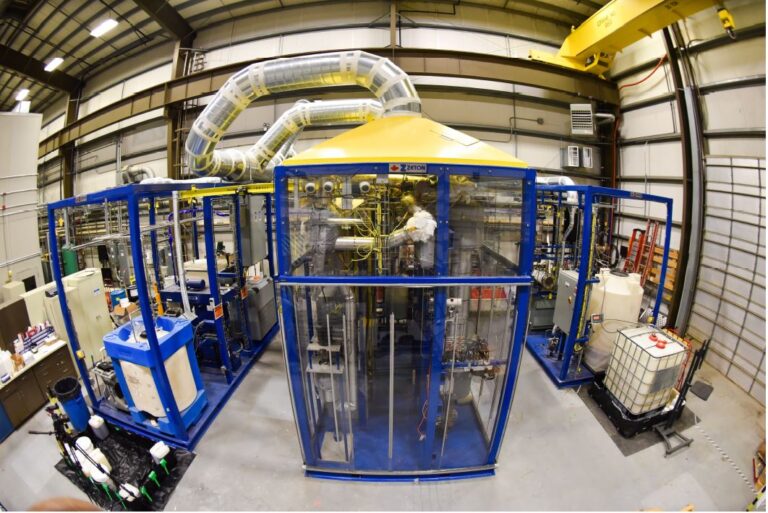

The Modular Hydrothermal Liquefaction System (MHTLS) is designed to convert wet feedstocks (e.g., organic wet wastes, algae, or wood) into biocrude and operates continuously, comprising three stages: Feed Preparation (Skid 1): Involves milling solids in an aqueous slurry using equipment like the Hockmeyer Mill to prepare them for HTL processing. HTL Processing (Skid 2): Biomass slurry feedstock undergoes pressurization and heating in reactors to HTL conditions, producing biocrude and byproducts. Skid 2 offers configurations for optimizing product yield. Product Separations and Storage (Skid 3): Separates the liquefied product into aqueous byproducts, biocrude, and non-condensable gas phases. Specialized separators and filtration systems ensure efficient separation, with biocrude and aqueous phases stored separately.

Overall, MHTLS provides a continuous process for converting wet wastes or biomass into biocrude, a precursor for various finished fuels, including Sustainable Aviation Fuel (SAF).

Capability Bounds

The process can operate liquefaction up to subcritical conditions (350°C) with wet waste feedstocks. The capability can format up to 1000 L of feedstock, generate up to 100 L of biocrude, and create 500 ml to 20 L of fuel blendstocks.

Unique Aspects

- Modular Design: allows for flexibility in processing different types of wet waste feedstocks

- Continuous Operation: Unlike many bench-scale systems that operate in batch mode, the MHTLS can run continuously 24 hours a day- increasing the system’s throughput

- Integrated Feed Preparation and Processing

- Advanced HTL Processing Configurations: MHTLS has flexible configurations for HTL processing enhancing the system’s applicability to a wide range of biomass materials.

- Integrated Product Separation

- Setup to Process BSL-2 Feedstocks

Availability

MHTLS is available to both the public and private sectors through the development of collaborative work scopes that utilize a variety of contractual mechanisms to meet the needs of the partners and funding agencies.

Benefit

MHTLS can be used to de-risk process scale-up. Useful for vetting feedstocks and process testing in scale-able engineering design of raw feedstocks to produced finished fuels and fuel blendstocks.

Capability Expert(s)

Sam Fox, Andy Schmidt, Mike Thorson, Dylan Cronin